One of the central tenets underpinning ISO 55000, the international standard for Asset Management, is that organisations perform better when there the goals and activities of all that work within that organisation are aligned. The better the connections between individuals and departments and overall organisational goals, then the better organisational performance will be.

Organisational alignment takes two forms – vertical alignment (a clear understanding of how what each individual does contributes to the achievement of the organisation’s overall goals), and horizontal alignment (ensuring that different functional areas collaborate towards the achievement of common goals). This article discusses each of these in turn.

Vertical alignment

Vertical alignment is frequently called “line of sight”. It involves ensuring that there is a clear connection between all activities that an individual performs within an organisation and the achievement of the organisation’s overall objectives. Even more than that, to be truly effective, the priorities that an individual assigns to the activities that they are performing are aligned with the priorities outlined in the organisation’s vision, mission, strategy and objectives. This perhaps seems like an unachievable nirvana, and it probably is, but the question that should be in all senior leaders’ minds is “how do we get closer to this ideal”.

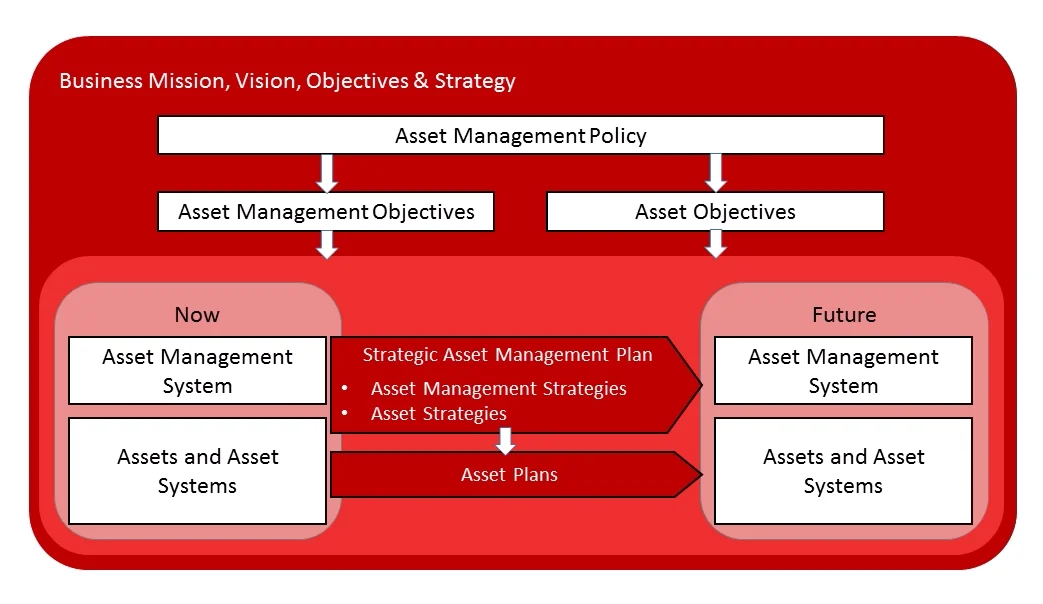

In the field of Asset Management, ISO 55000 suggests that the line of sight be driven through a connection between an organisation’s overall vision, mission, strategy and objectives, and:

- An Asset Management Policy (a high level statement of intent which provides guidance for lower level plans, policies, procedures and actions)

- Asset Management Objectives (key performance measures or outcomes for Assets and the Asset Management system which must be achieved if the organisation is going to achieve its overall objectives)

- A Strategic Asset Management Plan (a document which outlines the strategic initiatives and actions for the Asset Management System and for Critical Assets which are required in order to bridge the gap between desired Asset Management outcomes and objectives and what the results would be in those areas in the event of a “do nothing, business as usual” situation.

- Asset Management Plans (whole-of-life or longer term plans for the management of critical assets which outline what must be done to those assets in order to ensure that those assets continue to meet their required performance targets in terms of cost, performance and risks and therefore contribute to achievement of the specified Asset Management Objectives and through those, achievement of the organisation’s overall objectives.

This hierarchy can be visualised as below:

Horizontal alignment

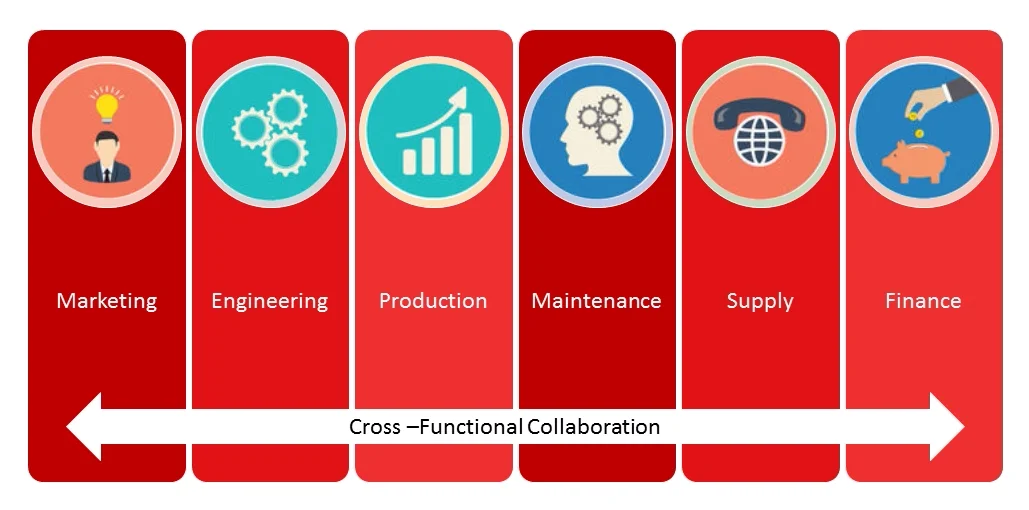

One of the biggest barriers to effective Asset Management is the existence of organisational silos – a failure to align the objectives and activities of the various departments and functions involved in the specification, design, procurement, construction, installation, commissioning, operation, maintenance and disposal of assets.

The typical functions involved in these activities include:

- Marketing/Sales

- Engineering

- Production/Operations

- Maintenance

- Supply/Procurement/Warehousing

- Finance

To a certain extent, the vertical alignment activities outlined in the previous section assist with breaking down the barriers between some of those functions. As the process of asset planning is asset-centric, and focuses on whole-of-life activities (which embrace demand forecasting, development of engineering solutions, production and maintenance forecasting and improvement etc) then this brings those functions together to develop the plans.

However cross-functional collaboration in the planning process does not necessarily translate to cross-functional collaboration in operations. Further work is required to ensure that functional goals and objectives, KPIs and reward systems are aligned and aimed at the achievement of optimal performance for the organisation as a whole. For example, having a target for the value of spare parts holdings will not necessarily be optimal for the whole organisation unless the cost of stockouts is included in the assessment. Nevertheless, the cross-functional coordination required for effective asset planning forms a sound foundation for further collaboration and coordination in other business activities.

The role of integrated information systems

So how do integrated information systems fit in with ISO 55000 and assist with building horizontal and vertical alignment within organisations?

First, a truly integrated system allows cross-functional collaboration by permitting the data that is generated by one part of the organisation to be used for better decision-making in another part of the organisation.

For example, engineers working on specifying and designing a new item of plant may be able to see and easily use data for similar plant that is already in use within their organisation to guide their decision-making. For example, they may be able to use operating cost data or maintenance cost data to perform whole-of-life cost analysis when comparing alternative design or specification options. They may also be able to see post-installation modifications that have been made to previously installed equipment and incorporate these within their new designs or specifications.

As another example, those procuring spare parts may be able to compare and contrast the reliability performance of alternative manufacturers, and determine whether there is value in spending more for higher quality parts that provide higher levels of reliability.

Second, ISO 55001 clearly states that data and information should be collected in order to ensure that:

- stakeholders’ needs for information and reporting are met, and

- the organisation can meet its asset management and organisational objectives.

It therefore makes sense that these should be the starting points for determining what data and information you need, and for designing the systems and procedures for collecting, managing and analysing this data and information. This is, in essence, a top-down approach, and if followed, will ensure that information systems facilitate clear line of sight between the data that is being collected and processed, the decisions that are being made, and the achievement of overall asset management and organisational objectives.

This is particularly the case with the convergence of Operational and Information Technology, which, when fully enabled will allow technical decision makers to make decisions which consider the financial and business implications of those decisions, and financial decision makers to better understand and assess the technical implications of the financial decisions that they make.