Effective maintenance planning and scheduling will deliver a safer and more cost effective work environment for asset-intensive businesses.

The benefits of having this function within an organisation can include:

- Safer Workplace – Planned work is inherently safer to perform than unplanned tasks

- Labour Productivity increases up to 60%

- Ability to collect and analyse data for failure analysis/trending

- Accurate Budget Forecasting

- The ability to measure workload and compliance to process (KP

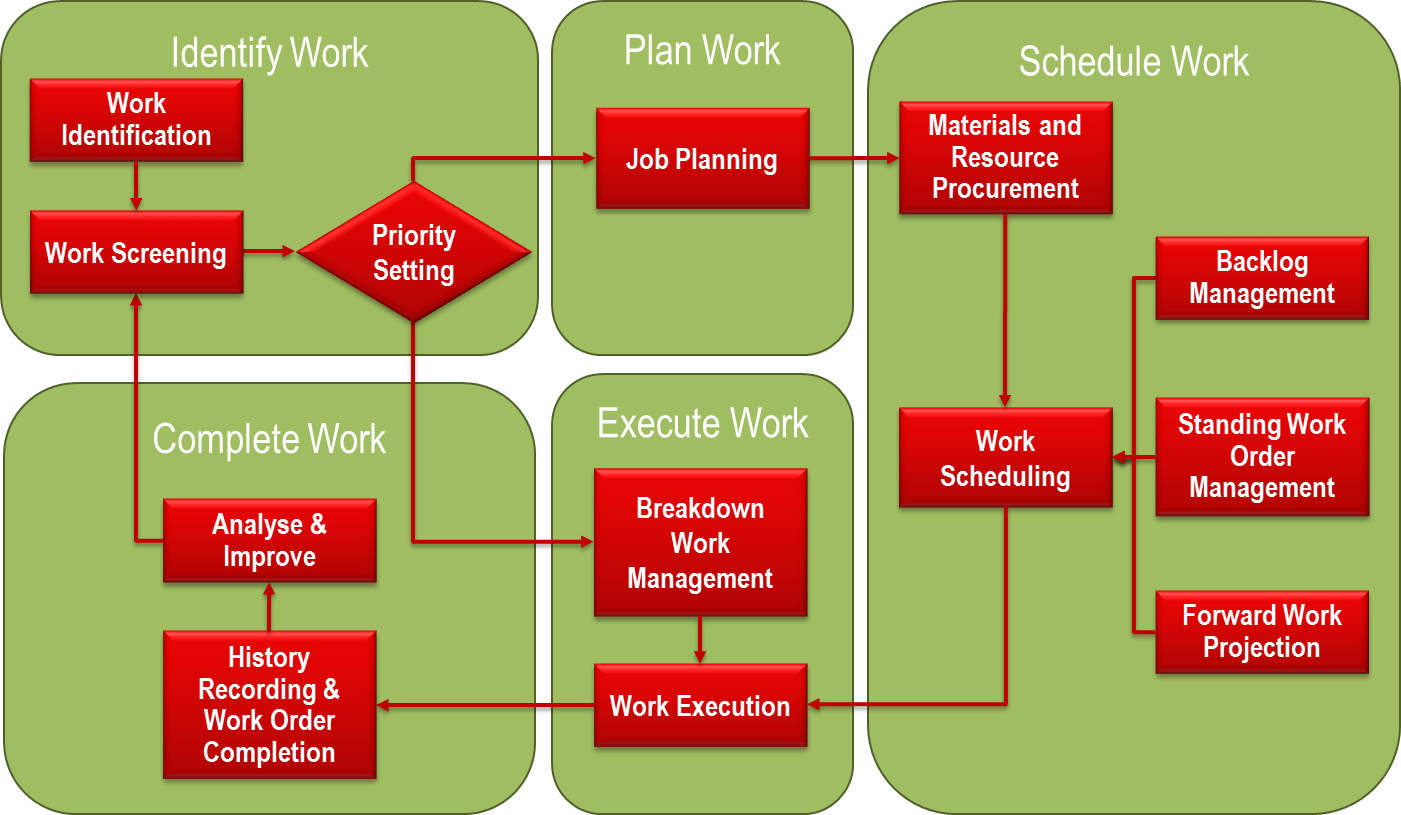

The Planning/Scheduling process can be visualised as illustrated below.

Delay Avoidance is the basic goal of Planning and Scheduling

The prime objective of good maintenance planning and scheduling is to allow maintenance personnel to prepare and perform the required task in a safe and cost effective manner without encountering time wasting delays.

Here are five tips that can make you a more effective Planner/Scheduler.

1. Understand your logs and what work they contain

Planners will typically utilise a large list of work that can be broken down into two categories:

- Back Log – Any work listed that has an execution date prior to today’s date

- Typically the back log will contain work that was not executed before its scheduled “due by” date or have cost settlement issues that will not allow the closure of the work order. This list needs to be monitored regularly to ensure the identified work is rescheduled accordingly. These jobs will often have to be pushed into the next planning period due to a new priority status being assigned when execution is missed. Some Backlog may be unavoidable, but it should be as small as practicably possible.

- Forward Log – Any work listed that has an execution date ahead of today’s date

- This list will be the main body of work that requires a planner’s attention. This work, if it has arisen from notifications or work requests, should have been approved by someone prior to requiring planning (generally the Maintenance and/or Operations Supervisor). You should ensure that the job is adequately scoped enough for you to safely and cost effectively plan the job for execution, if the information is not adequate you will need to seek further information from the approver or originator of this work before you can act.

Remember the adage: “Do it right the first time”.

Some thought needs to be applied to this log and good practice is that you forward schedule these work orders so that they are scheduled to be executed as close as possible to the date that the parts (or other scarce resources) required to do the job will be available. This, obviously, means that you need to know when these will be available before you schedule the work order. In some cases, we have seen planners push the scheduled start date for all jobs that are awaiting parts to months in the future; this will cause all sorts of cost and labour resource issues within CMMS and ERP systems.

Standardise the layout of these logs wherever possible so abnormal work will stand out visually when you are looking at the work in them. Some possible ways to do this are:

- Naming Conventions, insert a prefix before the work description to segregate packages of work (e.g. “ Shut Refurbish Pump 001”)

- Use of Revision numbers to allocate a work week period to the tasks (e.g. 2016W17 means Week 17, 2016)

- Make use of the System and User Status codes that your CMMS/ERP system provides (e.g. the WMAT user status code indicates that the task is awaiting materials

These standardisation techniques will save you time and take away the pain of having to interrogate each task to understand what it means and when it needs to be done.

2. Build a culture of teamwork with your supply function

Parts and Materials are one of the most important aspects of successful planning and scheduling. It is a “cardinal sin” for a planner to plan and schedule a task and either not order the required parts or misread the expected delivery date. The end result is a task that cannot be performed and rework will need to be performed.

Given the importance of this a lot of organisations are ensuring that their supply/warehouse personnel attend the maintenance planning/scheduling meetings that occur each week. In some cases a Materials Coordinator role has been established to ensure there is supply/warehouse buy-in at these meetings and that missed items or delayed parts are identified prior to locking in a planned maintenance schedule. This arrangement can be extremely useful and can complement continuous improvement initiatives where a Root Cause Analysis investigation is performed whenever materials issues have caused work to be deferred. Just like planners, these Materials Coordinators have KPI measures that they will be measured against. For the business it is a win-win situation in reducing delays and ensuring that work is performed safely.

If it is not already in place, we strongly recommend fostering a great working relationship between Maintenance and Supply, as both departments will benefit from this, as will your organisation overall.

3. Measure results and process adherence

Measure, Measure, Measure

It is very difficult to visually appreciate how well a process is working unless you put some meaningful Key Performance Indicators in place. The idea of these is not to chase the “Green” compliant result but rather focus on the barriers to process adoption that are preventing the achievement of good outcomes. Often there will be circumstances that will see a KPI measure go backwards rather than the desired direction but it will alert all concerned that there is an issue that needs to be fixed in order to move forward.

Root Cause Analysis (RCA) and similar techniques can then be utilised to analyse the problem and pinpoint the issue. This may sometimes require a business case to Management for release of funds and labour to fix it. Without the accompanying measurement data it will be a very hard sell!

Once a process has been proven to work and the group is achieving the “green” result it is a great time to move onto a new measurement. There is a very real risk of complacency and you can think you are doing well but a deeper dive into the process will often show the opposite. Keep challenging the status quo of KPI measures and if they are not meaningful or relevant why are we using them?

4. Forward schedule to an agreed period

From the forward log of work there will be an expectation from every organisation that you plan ahead to an agreed period. Some very mature organisations with reliable equipment and processes will demand a longer forecast period – in this case up to 12 weeks, or even longer for major shutdown work. However, this forecast period could be as little as 2 weeks. Regardless of the length of the forecast period the aim is to have fully planned and resourced tasks that can be executed during that period.

Getting all of the work in forward log fully planned and scheduled is the nirvana state as it will reduce the effort required to keep on top of this each week.

As an example: We have fully planned all work in forward log out to 8 weeks and have resourced the period to 85% of labour utilisation (to allow for breakdown work). In theory the planner will only need to keep up with new work that is generated during the week to keep the plan up to date. There will be a need to manipulate scheduled execution dates as emergent work is fitted into the forecast period. This will highlight the need for accurate priorities to be assigned to tasks. Overall, however, planner workload will diminish allowing more time to be spent on continuous improvement items.

One thing to remember is that if your forecast is for over 12 weeks of work at very high labour utilisation this can indicate that the forecast workload is out of balance with the labour available for its execution. If this occurs the planner will spend a lot of time rescheduling work orders and deferring maintenance work to the point that it is unacceptable to the business. Additional maintenance labour may be required to bring future workload back to a manageable level.

5. Analyse completed work and continuously improve

This area is where business can get the “best bang for their buck” but is often hampered by time constraints on planners as they struggle to meet schedule deadlines.

As part of the Continuous Improvement Process, maintenance planners need to analyse the work performed with the responsible Supervisor(s) and quickly make changes to any items that need attention. Performing these changes will ensure that tasks will run smoothly when executed next time.

Why do we do this? A definition of insanity is to do the same thing over and over again expecting a different result! Items that may need changing would be:

- Task Duration

- Materials or quantity of materials

- Work steps out of sequence

- Labour requirements under/over resourced

- 3rd Part requirements: scaffold, hire equipment, cranes, extra labour

- Master data changes to strategies and plans

Conclusion

I hope that this article has given you some useful tips for better Maintenance Planning and Scheduling. Implementing these can make your job as a planner more productive and satisfying, and also help your organisation to reduce costs and be more effective. If we can help you be more effective as a planner, contact us. Or you may want to consider attending our Maintenance Planning and Scheduling Excellence training course where we give you even more practical tips on how to be a more effective Maintenance Planner and Scheduler.

-

Product on sale

Maintenance Planning and Scheduling Excellence$1,935.00 – $2,150.00

Maintenance Planning and Scheduling Excellence$1,935.00 – $2,150.00 -

Product on sale

Introduction to Maintenance Management$967.50 – $1,075.00

Introduction to Maintenance Management$967.50 – $1,075.00