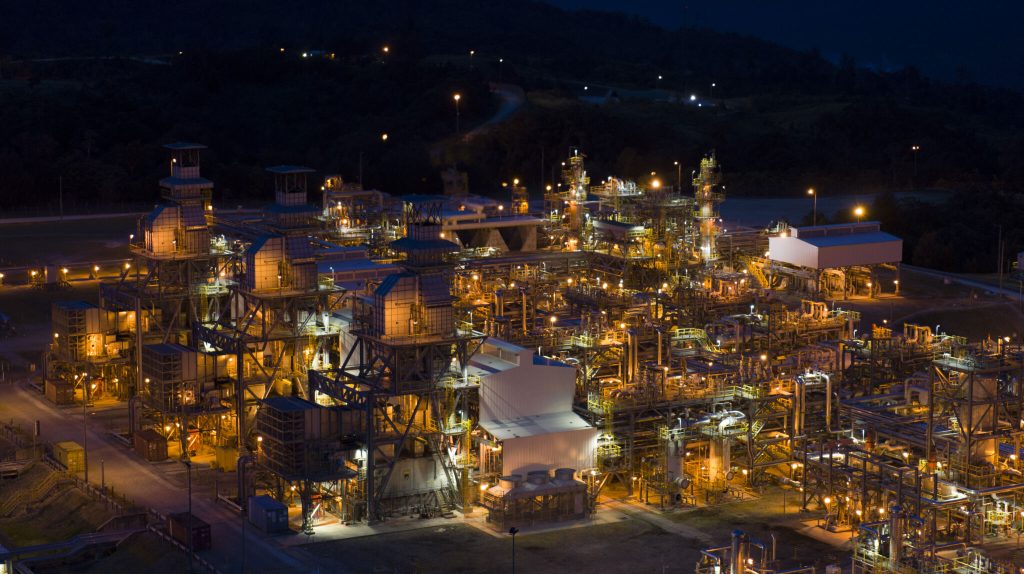

Santos is one of the leading independent oil and gas producers in the Asia-Pacific region, supplying the energy needs of homes, businesses, and major industries across Australia and Asia. With its origins in the Cooper Basin, Santos has one of the largest exploration and production acreages in Australia and extensive infrastructure and is committed to supplying the domestic markets, unlocking resources and driving value and performance.

Beginning in 2010 Santos commenced development of its Coal Seam Gas (CSG) resources in the Bowen and Surat basins of Queensland, development of three major gas compression facilities, construction of a 420km long gas transmission pipeline, and construction of a 7.2Mtpa LNG plant at Gladstone to liquefy CSG prior to its shipment to Asian customers.

The challenge

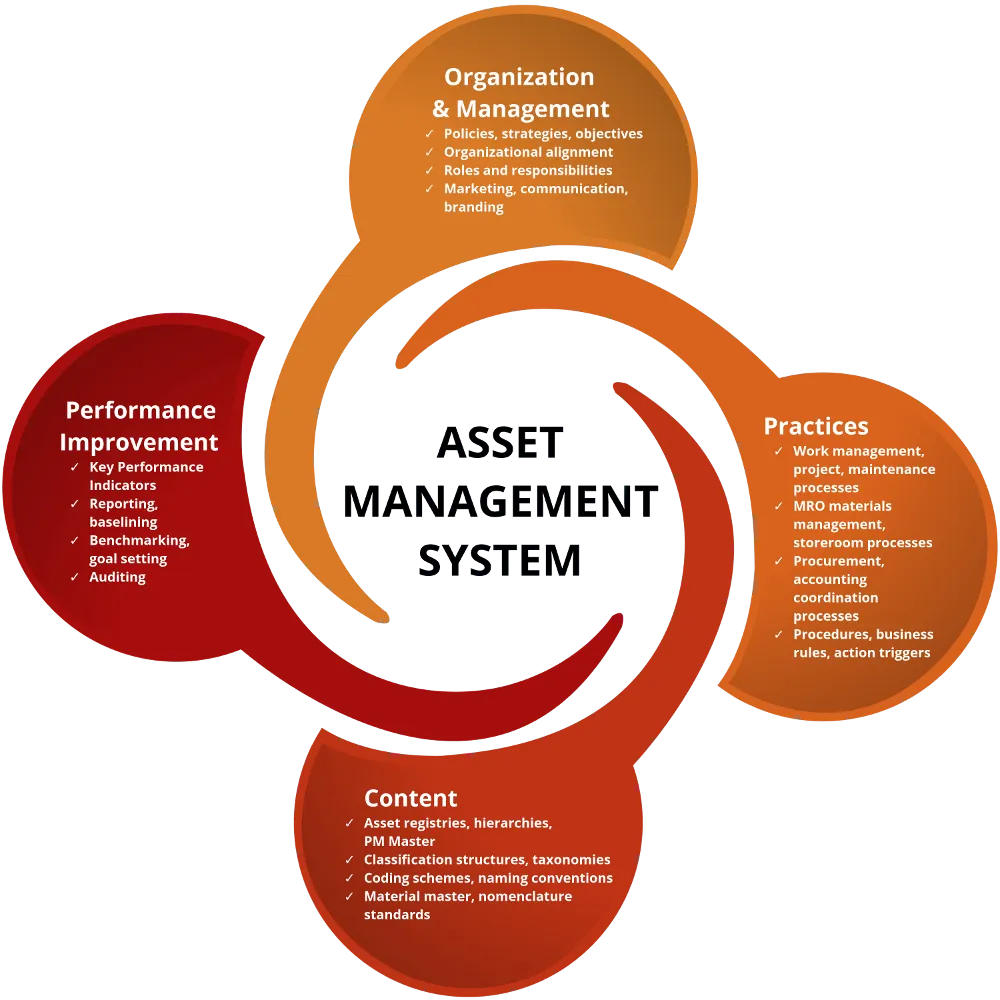

As part of the operational readiness process, Santos identified the need to develop effective maintenance and integrity management plans to assure the reliability and integrity of the new facilities. In order to achieve this, Santos implemented the GE Vernova’s Asset Performance Management (APM) software and selected us as one of its partners to assist with undertaking a range of operational readiness activities for all the GLNG gas extraction, transmission, and processing supply chain systems.

The solution

We assisted Santos with developing and/or implementing the following processes:

- Asset Hierarchy Development – Identification of all new assets and creation of functional hierarchies for upload into Santos’ enterprise Asset Management System (eAMS).

- Asset Strategy Development – Reviewing newly created asset hierarchies using a simplified Reliability Centered Maintenance (RCM) approach in the Meridium APM software to develop applicable and effective maintenance plans.

- Maintenance Work Packaging – Packaging maintenance plans into logical blocks of work to be executed under work orders created in the eAMS system.

- Spare Parts Identification and Optimisation – Identification and cataloguing of all spare parts required to support the maintenance of operating assets. This included spare parts optimisation processes to minimise the inventory held in Santos stores.

- Development of Reliability Management Plans – Development of reliability management plans that provided a summary of key information required by Senior Management on the expected performance of Santos’s assets. These detail:

- What output is expected to be provided by the asset?

- What are the key risks with the asset and how does the developed plan reduce this risk?

- What reliability is expected from the asset?

- How many people are needed to support the preventive maintenance program for the asset?

- How much will it cost to sustain the preventive maintenance program?

- What inventory is required to be held in order to support the required asset reliability and its preventive maintenance program?

Benefits and outcomes

As a result of our efforts, Santos has been able to achieve the following outcomes relating to its new GLNG systems:

- Implementation of maintenance plans that are ‘applicable and effective’ through the use of risk based processes.

- Maintenance tasks have been appropriately packaged into manageable portions to minimise site visits and asset shutdowns whilst ensuring work packages are levelled around available resources.

- Materials required for the performance of maintenance activities have all been identified and catalogued to reduce the time planning resources and field staffs have with searching and acquiring the correct parts.

- GE Vernova’s Asset Performance Management (APM) has become the central repository and source for maintenance and reliability information ensuring standardised maintenance support and development efforts in the future.

- The creation of a concise RMP for each asset class provides a basis for performance guarantees between Reliability, Operations, and Senior Management to support future asset management decision making processes.

As a result, Santos is expecting these facilities to achieve high levels of reliability right from the commencement of operations.

Looking for help with achieving high levels of reliability for your new systems?

We offer a comprehensive range of consulting services relating to maintenance, reliability and asset management. If your needs are comparatively straight forward, we have standardised approaches for delivering these services that provide demonstrated results as quickly and cost-effectively as possible. Browse our services below to explore how we can help to achieve your goals.