As a trainer I’m sometimes surprised by the answers to two simple questions from skilled personnel from planning and scheduling departments attending Planning and Scheduling training.

The first being, “What is Planning?”.

And the second, “What is Scheduling?”.

In most cases people get the gist of the concept correct, but there are always a few who muddle or confuse the two concepts.

One reason could be that the difference in the two concepts has never been explained or because people do not see it as two separate concepts. Another reason for this could be where one person is responsible for both these functions without having a clear understanding of the boundaries of each. “It’s the planner’s job, right?”

Do not get me wrong, the planning and scheduling function could be performed by the same person, but only if they understand the differences in the processes and when they should be wearing which hat – planning or scheduling.

I’m sure you’re asking, “Why is this a problem?”.

Well, many organisations struggle to get out of the reliability death spiral where all they can focus on is breakdowns. The main reasons for this are ineffective maintenance strategies, as well as ineffective planning and scheduling processes. Performing the wrong maintenance, in the wrong way, at the wrong time.

Many organisations do not even have a defined planning or scheduling process with all jobs seen as being equal and maintenance personnel scoping and performing the tasks when received. This leads to spares not being available to perform the task, equipment not being available and sporadic resource loading. All this in turn leads to unnecessary operations delays and wasted money.

If we cannot even get the basics right, how can we expect to get out of fire fighting mode into being more proactive.

So, how do we ensure that the two processes in the control of the Planning and Scheduling department are performed effectively? By understanding the function and boundaries of the two processes. Let’s go back to my original two questions.

What is planning?

Planning is deciding “What to do”, “How to do it” and the “Resources” required.

- What – What maintenance tasks are required to restore or maintain the function of an asset. This could be preventive or reactive tasks.

- How – What are the steps involved in performing the task.

- Resources – What skills, tools or additional equipment are required to perform the task safely.

In addition to the items listed above you need to estimate the duration of the task, as well as order or reserve the spares or other resources required for completing the task as part of the planning process. This is where the planning function ends.

What is scheduling?

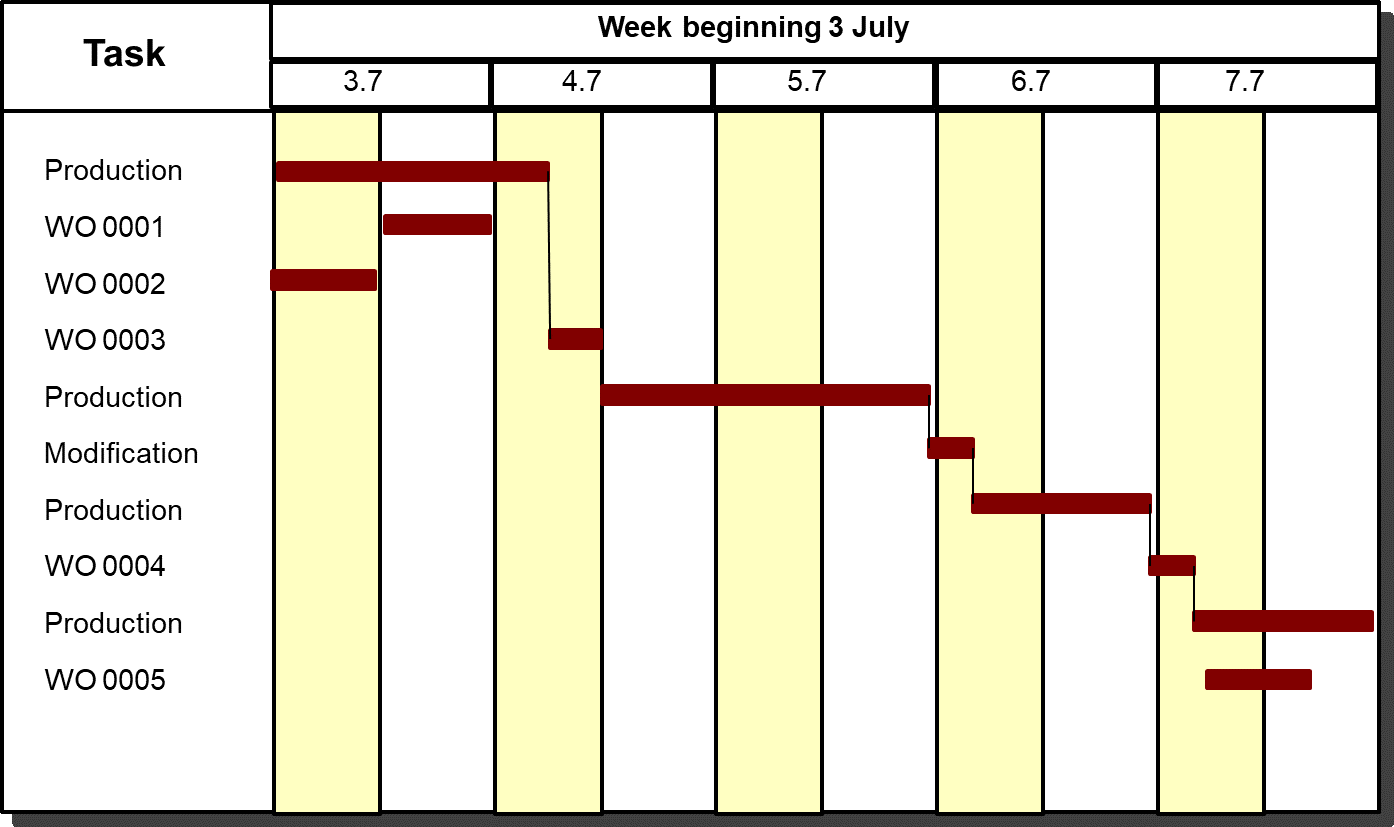

Scheduling is “When to do the task” and the “Specific resources to be used”.

Scheduling is “When to do the task” and the “Specific resources to be used”.

You will notice that I did not specify when the task will occur when I explained what planning is. You have planned the “What” and “How”, as well as ensured that all resources and spares were ordered during the planning phase. But the scheduling process focus on agreeing on a timeslot to perform the task with the specific resources available once all spares etc have arrived. The tasks will form part of the organisations backlog (preventive, corrective, predictive, modifications) and should be scheduled based on priority.

This is the only function of the scheduling process – aligning specific resources, tasks and available maintenance time slots.

Getting the basics right

By ensuring that the basic concepts and responsibilities are understood by all, as well as understanding the limits and interdependencies of planning and scheduling as part of the larger work management process, you will be able to increase the effectiveness of how maintenance is performed.

I have touched on some of the basic requirements of the Planning and Scheduling process, but there are many links with other items within the Work Management process that need to be considered.

If you would like to know more on the do’s and don’ts of the planning and scheduling process and how it fits in the work management process, consider attending our Maintenance Planning and Scheduling Excellence course or contact one of our professional consultants should you require some assistance in developing or improving the way you do planning and scheduling.

-

Product on sale

Maintenance Planning and Scheduling Excellence$1,935.00 – $2,150.00

Maintenance Planning and Scheduling Excellence$1,935.00 – $2,150.00 -

Product on sale

Introduction to Maintenance Management$967.50 – $1,075.00

Introduction to Maintenance Management$967.50 – $1,075.00