There are few activities on the maintenance calendar that pose a bigger risk to your production than shutdowns. They consume resources, create downtime, and are often plagued by over-runs and restart issues. So before you take that risk again, have a read of this article and be sure you are doing it for the right reasons.

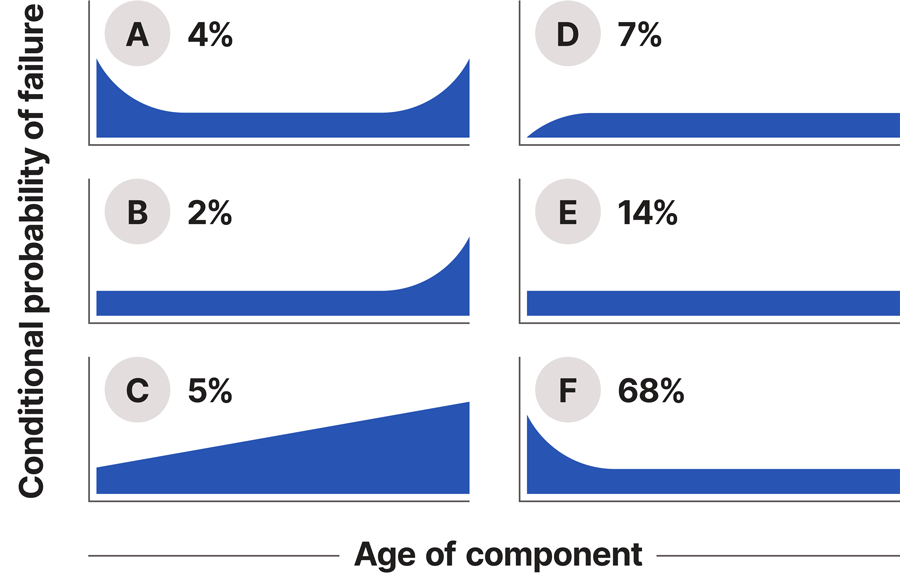

Most people would be aware of the six failure curves from the study Nolan and Heap conducted in the late 1970’s. Here is a quick summary for those unaware:

In 1978 Nolan and Heap published a report for United Airlines. The report contained information on the conditional probability of failure against operating age for a variety of electrical and mechanical items in the aviation industry.

Basically, the report’s findings challenged the commonly held belief that item age and likelihood of failure were directly related.

‘So what, I’m a miner’ I hear you say. Well the good news is that the report’s findings don’t just apply to equipment in the aviation industry. They were far wider ranging and formed the basis for what we know as reliability centered maintenance, or RCM.

Arguably the most interesting Nolan and Heap finding was that 68% of items conformed to failure pattern F – an infant mortality failure pattern.

So what are some of the reasons for such a high incidence of early life failures, and more importantly what can we do to prevent them?

Moubray provides some suggestions on the reasons:

- Excessively invasive maintenance

- Unnecessary maintenance

- Incorrect installation

- Incorrect commissioning

- Bad workmanship

- Poor Design

- Poor manufacture quality

Now, no matter what your business; if you need to maintain assets; some, if not all of these reasons will be applicable to you. With that in mind, have you asked yourself the important ‘why’ question?

Why are you shutting down?

A great deal of infant mortality is caused by routine maintenance tasks which are either unnecessary, or unnecessarily invasive. The latter are tasks which disrupt or disturb the equipment, and so needlessly upset basically stable systems. The way to avoid these problems is to stop doing unnecessary tasks, and in cases where scheduled maintenance is necessary, to select tasks which disturb the equipment as little as possible.

Moubray, 1997, p. 248

Shutdowns are conducted to complete one or more key tasks that can only be performed safely while the plant is non-operational. Sounds obvious, however, you might be surprised at how much of your current shutdown work list can be accomplished outside of your shutdown through some innovative thinking. My recommendation: Before diving head long into the planning phase of your next shut down, spend some time with your plant experts. These are the guys that have been around a while and have inside knowledge of the equipment. Get their assistance in identifying work that can be carried out without exposing your business to the risk of a shutdown. Eliminate some of that ‘unnecessary maintenance’.

Now don’t get me wrong. I’m not advocating removing all non-shutdown related work from your shutdown work list; quite the opposite in fact. If a shutdown is unavoidable take full advantage of the opportunity. Get some of those ‘harder-to-do’ tasks off of that ‘to-do-list’. Just make sure the work is needed, and you’re doing non shutdown work consciously. In shutdowns we need to ensure we are setting ourselves up for success, and this starts as early as the work identification phase of the shutdown.

Another important aspect often forgotten is ensuring all shutdown, and non-shutdown related tasks are clearly identifiable and correctly prioritised. We know shutdowns are risky business, and our businesses should not be exposed to risk unknowingly. By prioritising the work and making sure it is easily identifiable as critical or non-critical we can ensure that we’ll have suitable information to make the best decisions possible during the heat of execution.

Ok, you’ve scoured your shutdown work list and purged all those high risk, low return jobs. You’ve spent time with your plant experts and clearly identified what tasks are critical, and what tasks are not critical. Do yourself a favour and take some time to place each job in to one of the following categories:

- SHE Tasks – These tasks are performed with the goal of improving the safety, health and environmental performance of the Plant.

- Statutory Task – These tasks are completed to ensure compliance with regulatory requirements is maintained.

- Efficiency Task – These are the jobs you are doing to reduce overall Production or Maintenance costs.

- Reliability Tasks – These tasks are being performed to maintain or increase the equipment’s reliability through to the next planned outage.

- Capacity Task – These tasks are completed to increase the Plant’s production output.

If it is not immediately obvious which category a job fits in, chances are it isn’t a job that belongs in your shutdown, or on your backlog list at all!

References

Moubray J, 1997, Reliability-centred Maintenance. 2nd ed. Oxford: Butterworth-Heinemann.