Choosing the right tools for the job

There is little point in having a strategic vision of where you want to go, combined with fully aligned reward systems, unless you actually allow your people, at all levels, to learn and then apply their new learning to their realm of influence. We are fortunate here, because consultants and vendors have created a wealth of tools and techniques which, if properly implemented, can allow the acquisition of new knowledge and skills, and then permit the application of these new skills.

This is the fifth in a series of 6 articles on moving from a repair-focused to a reliability-focused culture.

Articles in this series

The challenge facing maintenance managers today is not in finding methodologies and approaches to apply, but in understanding how they all fit together. It also lies in making sure that the application of these approaches are not seen as the latest fad, project, or “flavour of the month”, but are fully adopted and internalised within organisations, and simply become “the way we do things around here” in certain, appropriate, situations.

Tailoring a solution for your organisation

Despite the overconfident claims of some consultants and vendors, there is no single tool, software package or methodology that will solve all your problems, and magically transform your organisation overnight into a truly reliability-focused organisation. Every organisation is different and faces its own challenges. Industries are different, people are different, their histories are different. Thank goodness for that – life would be pretty boring if that weren’t the case!

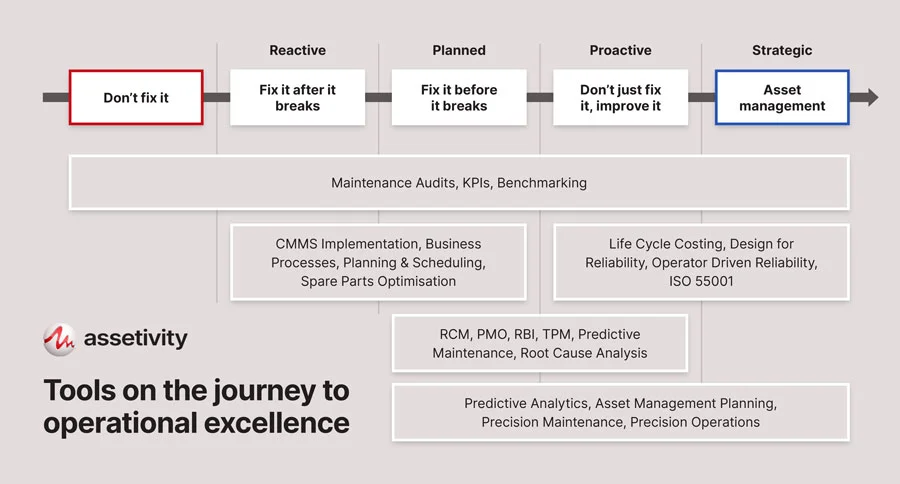

Having said that, though, there are some tools and techniques that are more likely to be applicable in certain situations. Once again, with reference to the Ledet path from Repair-focused to Reliability-focused culture, Figure 3 below outlines a possible way of looking at some of these tools and techniques, and where they may apply in this journey.

Many of these tools, methodologies and techniques lend themselves to the provision of opportunities for building teamwork between Production, Maintenance and Engineering personnel at all levels. Many also provide the opportunity for the acquisition of new, higher level skills among maintenance tradespeople and plant operators. Effective maintenance managers will select the tools that are appropriate to their situation and ensure that these opportunities for engagement and growth amongst personnel at all levels within the maintenance and production organisation are fully adopted where appropriate. They are also likely to ensure that disciplines, systems and procedures are in place to ensure that the application of these approaches are consistently applied, on an ongoing, long-term basis, when it is appropriate to do so.

There is not sufficient time or space to discuss all of these methodologies and approaches in detail, but I would like to take the opportunity to discuss one or two of these, albeit briefly.

Implementing reliability centered maintenance (RCM)

There is hardly likely to be a professional maintenance manager today that has not heard of Reliability Centred Maintenance – RCM. For many who have tried it, RCM stands for “Resource Consuming Monster”. Yet the underlying engineering principles, and the fundamental implementation philosophy of RCM are sound. It relies on the application of a breadth of knowledge regarding the operation and maintenance of a piece of equipment through small, multi-disciplinary teams, usually involving experienced shopfloor tradespeople and operators, as well as other people who have technical knowledge of the equipment, such as engineers, supervisors, and vendors. As such, the training and implementation approach associated with this tool provides an outstanding opportunity for organisational and individual learning and growth. It’s just a pity that it takes so damn long to do the analysis!

Implementing preventive maintenance optimisation (PMO)

An alternative approach to the implementation of RCM principles, which also embodies the same philosophy of using small, multi-disciplinary work teams, but which applies these principles in a far more time-effective manner, and results in similar, or better, results in almost all situations, is PM Optimisation. Once again, the combination of effective training, plus the establishment of focused implementation teams provides a highly valuable opportunity for individual and organisational learning and growth at all levels.

Several Root Cause Analysis techniques also promote the use of small, multi-disciplinary teams to solve, and eliminate, both one-off, catastrophic “failures”, and repetitive chronic failures. Included amongst these are techniques such as the Apollo method, Taproot and ProAct. Again, the secret to success in using these techniques is to ensure that people are properly trained in their application, and then to establish the organisational disciplines and procedures that ensure that these approaches are used whenever an appropriate situation arises that justifies use of a Root Cause Analysis tool.

If you are looking for further insight into RCM and PMO, we offer a short course for team members that covers the essential principles and best practices of each. To consider the bigger picture, refer to the other articles in this series:

Articles in this series