We, as Asset Management professionals, work with classified plant and equipment on a day-to-day basis, but are often not confident that we have accurately identified our classified plant or fully understand our obligations at each stage in the asset lifecycle.

This article discusses the key activities associated with the acquisition, operation, maintenance and disposal of classified plant and equipment. Let’s start by understanding why classified plant needs special attention.

Why do classified plants require special attention?

Classified plant and equipment is typically hazardous by nature and therefore subject to legally binding constraints on its acquisition, operation, maintenance and disposal. Poor lifecycle management can cause serious damage to plant equipment, serious injury or death, production losses, heavy fines and damage to a company’s reputation.

According to an evaluation of incident data by National Board of Boiler and Pressure Vessel Inspectors, for the period between 1992 and 2001, a total of 127 people lost their lives in the US as the result of boiler and pressure vessel accidents.[i]

In 2008, in Manhattan US, a crane cab came loose from its mast and toppled to the street below damaging neighbouring buildings as it fell. Two men were killed by the collapse. Initial reports blamed the failure of a shoddy turntable weld for the cab coming loose from the tower.[ii] In a more recent incident in New York US, a crane collapsed when the operators were in the process of lowering and securing it. The incident killed one person and injured three others.[iii] Could an effective inspection and test plan have prevented these incidents?

State and National regulatory bodies such as WorkSafe, NOPSEMA, ERAC and the Department of Mines and Petroleum can impose heavy fines and/or imprisonment for breach of any stated duties in the applicable acts for the management of classified plant by designer, manufacturer, seller or user.

Do you know your classified plant?

Many organisations are unfamiliar with the classified plant and equipment that they own and how they should go about managing their lifecycle activities. As a minimum, classified plant and equipment includes the following categories:

- Pressure Equipment e.g.

- Boilers

- Fired heaters

- Pressure vessels

- Gas cylinders

- Cranes e.g.

- Bridge cranes

- Gantry cranes

- Mobile cranes

- Tower cranes

- Lifts and work platforms e.g.

- Hoists

- Boom type elevating work platforms

- Elevating work platforms

- Mast climbing work platforms

- Electrical equipment as per the ratings specified under International Electro technical Commission (IEC)

How to effectively manage your classified plant

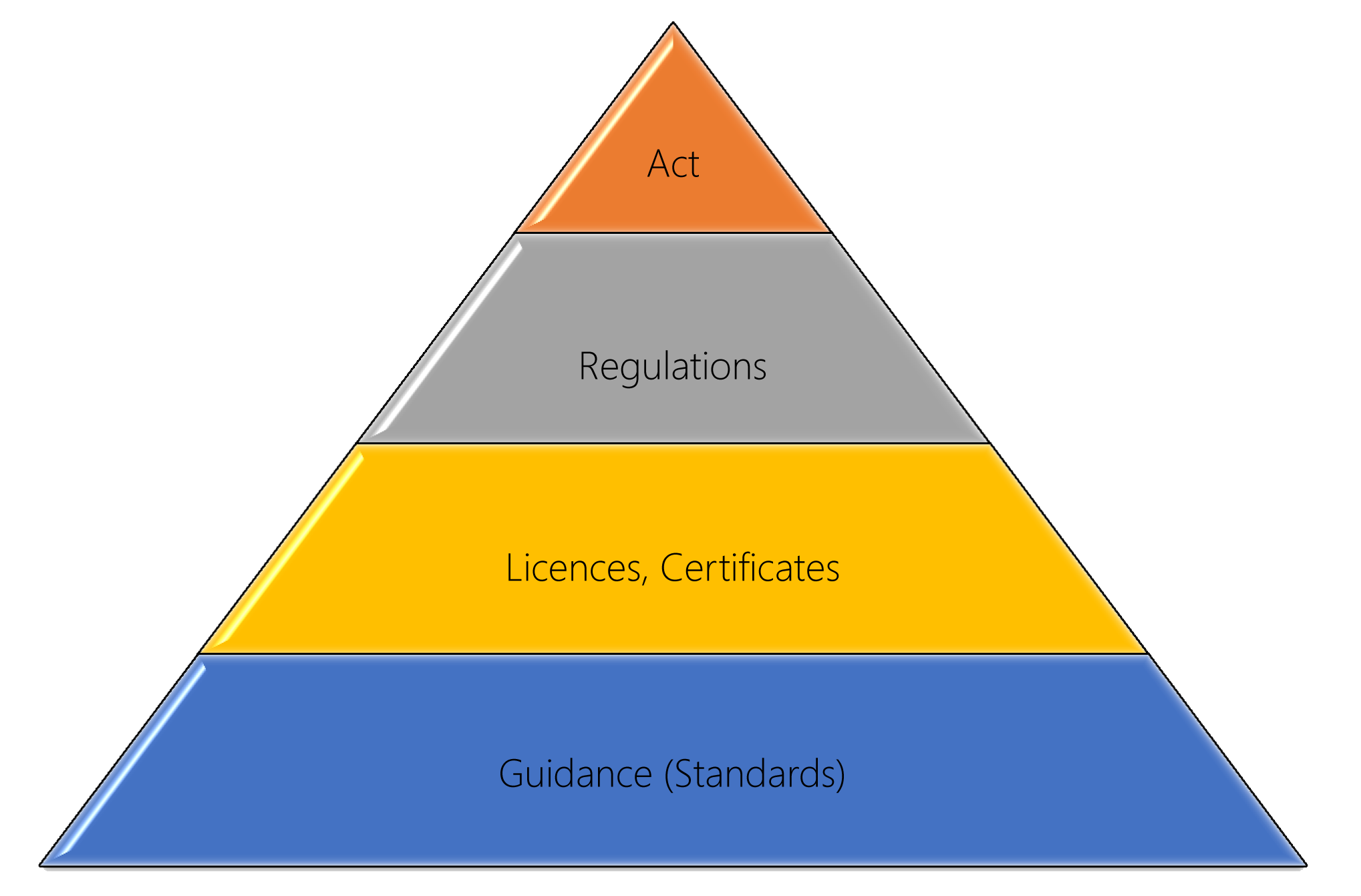

The legislation to be followed for the lifecycle management of classified plant is specific to the jurisdiction where its operation is located. The jurisdiction may involve laws at a country, state/province, or local level. Also there may be specific requirements for the organisation in its operating licenses and approvals.

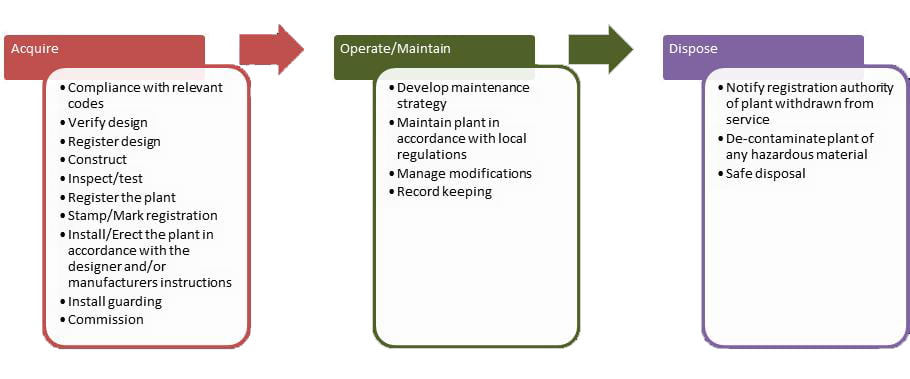

Like any other physical asset, classified plant has a lifecycle which consists of its acquisition, operation and maintenance, and finally its disposal.

Let’s start with the acquisition phase.

Classified plant and equipment is acquired in various ways. This could include:

- Direct purchase e.g. off-the-shelf items such as pressure safety valves, gas cylinders, accumulators.

- Design, Construct, Install type procurement contracts, where some or all of the acquisition activities could be outsourced.

No matter which way a classified plant is acquired, the owner/operator has certain responsibilities he should fulfil for effective and regulatory compliant lifecycle management of their classified plant.

The acquisition phase involves design, construction, installation and commissioning. Let’s now look at owner/operator’s key responsibilities for each of these elements.

Design

As an owner/operator of a classified plant you need to ensure that the plant is designed to appropriate standards and is fulfilling all applicable regulatory requirements before it can be constructed or procured. Some key responsibilities include:

- Ensuring that the plant is designed in compliance with the requirements stipulated by the applicable regulation. These requirements could include designing the plant to appropriate standards, example:

- Boiler – Australian Standard (AS) 1200, 1228

- Pressure vessel – AS 1210

- Crane or hoist – AS 1418

- Lift – AS 1735.

- Ensuring that the design is verified by a competent person.

- Ensuring that the design of the plant is registered with the relevant regulatory body where applicable, example: WorkSafe in Western Australia.

Key documentation that is required for registration of the design may include:

- Detailed drawings of the plant design

- Material specifications

- Design calculations

- Details of operating instructions

- Diagrams of control systems, including the sequence of operating the controls

- Details of maintenance requirements

- A statement of the limitations of the plant’s use

Construct

As an owner/operator of a classified plant you need to ensure that all key regulatory requirements are satisfied for the construction of the classified plant before it can be installed and operated. Some key responsibilities include:

- Ensuring that the plant is fabricated, inspected and tested in compliance with the requirements stipulated by the applicable regulation. These requirements could include constructing the plant to appropriate standards.

- Ensuring the personnel involved with fabrication, inspection and testing of the plant are competent. There could be a requirement for the personnel to be certified dependent upon the regulation or standards referred to in the regulation. For example: AS 1210 Pressure Vessel standard requires Non Destructive Tests (NDT) to be performed by National Association of Testing Authorities (NATA) certified personnel and welders and welding supervisors certified by an authorised body (WTIA).

- Ensuring that the plant is registered with the relevant regulatory body where applicable, example: WorkSafe in Western Australia. The kinds of plant requiring registration will depend on the applicable regulations. For example: Typically pressure vessels categorised as hazard level “A. “B” or “C” according to the AS 4343 standard and Boilers require registration with the applicable regulatory body in Australia.

- Ensuring, where the plant is registered, that the registration number is clearly stamped or marked on the plant.

- Ensuring that the key technical design and construction documentation of the plant is sourced and records are filed. As a minimum, this documentation should include:

- Design calculations

- Drawings

- Materials certificates

- Inspection, test, and defects reports

- Personnel competency records

- Design and plant registration certificates

- Design verification certificate

- Operating and maintenance instructions

Install and Commission

As an owner/operator of a classified plant you need to ensure that all key regulatory requirements are satisfied for the installation and commissioning of the classified plant before it can be operated. Some key responsibilities include:

- Ensuring that the plant is installed and commissioned in compliance with the requirements stipulated by the applicable regulation. These requirements could include installing and commissioning the plant to the designer’s/manufacturer’s instructions or to appropriate standards.

- Ensuring that guarding and operating controls are in place to manage or eliminate safety and environmental hazards.

- Ensuring that the key installation and commissioning documentation of the plant is sourced and filed. As a minimum, this documentation should include:

- Commissioning reports

- As-built drawings

- Inspection, test, and defects reports

The operate/maintain stage

As an owner/operator of the classified plant, the “operate and maintain” phase is where you have the most involvement. Proper care and maintenance is required to ensure all statutory obligations are met and the plant is operating in a safe and reliable manner. The following aspects need to be considered for effective operation and maintenance of your classified plant:

- Identifying classified plant using an appropriate indicator in your computerised maintenance management system (CMMS).

- When setting up classified plant and equipment maintenance program, ensuring:

- Preventive maintenance schedules are created for mandatory inspections on classified plant. These should:

- Have a frequency of no less than the requirements of the applicable regulation or the standards referenced in the regulation.

- Specifically detail mandatory inspection requirements.

- Be applied individually to the specific assets that they cover.

- Be able to clearly identify in maintenance history reports that specific assets were inspected.

- Preventive maintenance schedules are created for mandatory inspections on classified plant. These should:

- The preventive maintenance schedules are optimised using techniques such as Reliability Centered Maintenance (RCM), Preventive Maintenance Optimisation (PMO) or Risk Based Inspection (RBI). To learn more about this topic, read our article “RCM PMO and Preventive Maintenance Programs – 4 Key Concepts”.

- When carrying out any corrective maintenance on in-service classified plant, ensuring:

- Any inspection, repair and, where necessary, testing is done by a competent person.

- In case of damage or failure a competent person assesses the damage.

- Repairs and testing of the plant are done in compliance with the requirements of any applicable regulation. These requirements could include carrying out the repairs and testing to the designer’s/manufacturer’s instructions or to appropriate standards so that the original design limits in relation to the plant are not exceeded. Example: Any repair, inspection or alteration of an in-service boiler or pressure vessel in Australia is required to comply with the AS 3788 standard.

- Before the plant is returned to service, it is inspected and tested by a competent person.

- When carrying out any modification work (does not include routine maintenance, repairs or replacement) on an in-service classified plant, ensuring:

- The design of the alteration is as per the regulation or other standards referenced by the regulation.

- The design of the alteration is verified and registered as required by the regulation.

- The plant is re-registered as required by the regulation.

- All alteration works are performed as per the regulation and to standards referenced in the regulation.

- The plant is inspected and tested before returning to service.

- Record keeping: Ensuring that, as a minimum, the following information relating to the classified plant is stored (electronically in a document management system where possible):

- Original design and construction documentation

- Inspection, testing, and defect reports/certificates

- Preventive and corrective maintenance records including date and names of inspectors/technicians performing inspections

- Significant equipment maintenance, repairs and alteration records and supporting data (this does not include routine maintenance jobs carried out at regular intervals)

The disposal stage

When the classified plant is no longer required, as an owner/operator you need to ensure that the plant is disposed of safely and in compliance with applicable regulations. Some key responsibilities will include:

- Where the plant is registered, notifying registration authority of it been withdrawn from service.

- De-contaminating the plant of any hazardous material.

- Safely decommissioning and disposing the plant following your company’s safety and environmental policy and procedures, and/or in accordance with any applicable regulation.

Conclusion

Key to the effective management of classified plant is to understand the statutory requirements, applying discipline through the whole life cycle of the asset and ensuring cross-functional awareness of the implications of operating and maintaining classified plant. Also liaising and building relationships with regulatory bodies might prove invaluable to the success of managing classified plant.

I hope that this article has served as a useful resource for clarity on statutory obligations and good practices for lifecycle management of your classified plant and equipment.

If you feel that you need help optimising the lifecycle of your classified plant, call us and talk to one of our expert consultants or email us today.

For future useful articles sign up to our mailing list now.

[i] http://www.iaeng.org/publication/WCE2010/WCE2010_pp1120-1123.pdf

[ii] https://failures.wikispaces.com/Crane+Failures

[iii] http://www.abc.net.au/news/2016-02-06/giant-crane-falls-in-new-york-killing-one/7145694